Keeping your test probes in good working condition is key to making a reliable test and keeping probes at their optimum performance. Over time, in high volume production environments or even in low volume applications where the fixtures may be stored for months at a time, contaminants and debris can build up and cause false failures, yet you may not find any defects. To help reduce these contact problems, save time and money, QA Technology recommends the following:

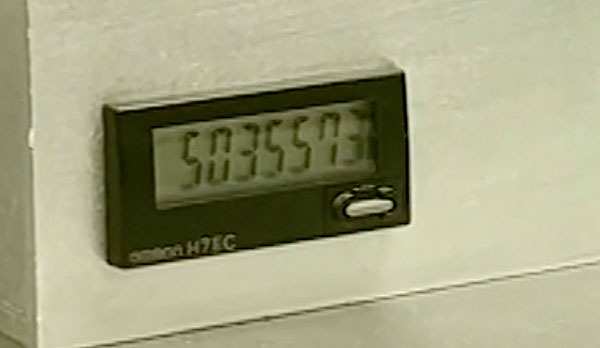

A practical maintenance program can save considerable time and money. This creates a more reliable test, reducing the chance of false failures and lost rework expense. Use cycle counters on test fixtures to help establish a routine maintenance program, whether it be cleaning the probe tips or replacing the probes after a predetermined number of cycles.

Developing a program requires some tracking to determine the average life of the probes in your application. Certain environments call for probe replacement as often as every few thousand cycles, while in clean applications probes can last far longer. Increased test yields and reduced downtime are the rewards for keeping probes in top condition.

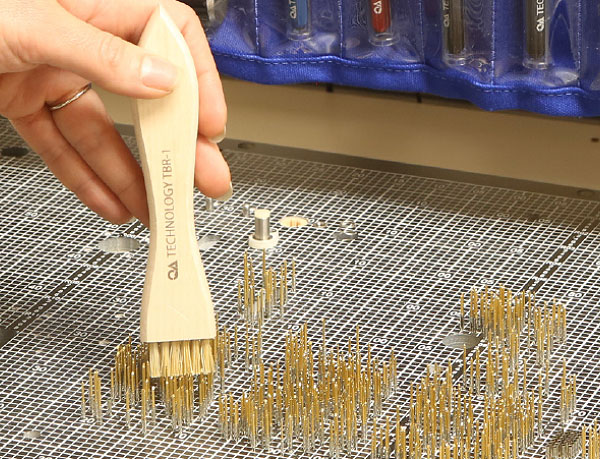

To clean the contaminants that build up on the probes, gently brush the probe tips with QA’s natural fiber brush (TBR-1) and vacuum away the dislodged particles. QA does not recommend the use of metallic bristles because they may damage the probe plating.

QA uses a small amount of lubricant to minimize wear caused by the internal sliding contact surfaces of our probes. Never use cleaning solvents on your probes as it may wash particles down into the critical internal surfaces. This could affect the performance and shorten the life of your probes.

Here are recommendations to help keep test probes clean and maximize cycle life:

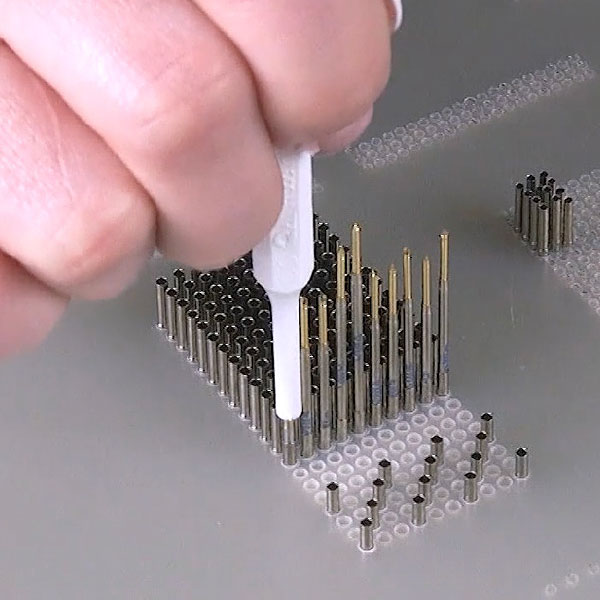

Eventually, you will need to replace probes. Do so when cleaning is no longer effective or when you record a decrease in performance. Due to their small sizes and features, worn, blunt or damaged tips may not be readily visible while spring fatigue will often show up as a plunger that does not extend to its full height after being compressed.

Diagnosing contact problems as they arise and replacing individual probes may work in the short term but as probes reach the end of their life, the added maintenance time is more expensive compared to a full maintenance schedule.

More details can be found in our video "7 Factors that Affect Probe Life". See Chapter 7 for Care and Maintenance.